This was one of my first questions almost 12 years ago when I first heard that a draftsman was an actual legit job!

Engineering Drawings are used mostly during the fabrication stages of a component / assembly or complete equipment (like a heat exchanger, storage tank, drum, engine, etc.) . The drawing is the link between the designer and the fabricator and conveys all the necessary information to the fabricator to manufacture correctly.

A second way how Engineering Drawings are used is for

maintenance or modification purposes. When a component broke or a part

of the component was damaged and the component must be restored to it’s

original strength and dimensions, a drawing is used to instruct the

fabricator what materials, sizes of the material, repair procedure and

final assembled dimensions should be used and be adhered to. This is

also used when a component is modified to improve it’s efficiency or

operation.

Anther way how engineering drawings are used may be for a company to give potential suppliers the specifications and information of something they want built and the drawing (together with a specification) is used to give to suppliers to tender for the building and installation.

How engineering drawings are used for fabrication:

For fabrication, engineering drawings are very detailed. Every component and step during the fabrication process should be addressed on the drawing. Engineering drawings will mostly be made in certain steps itself.

- All technical data will be listed on the first drawing of the set, this tells the manufacturer which Codes, standards and other requirements the design was created to.

- A Bill of materials (or bill of quantities) is listed to tell the fabricator what materials is required to manufacture what is on the drawing.

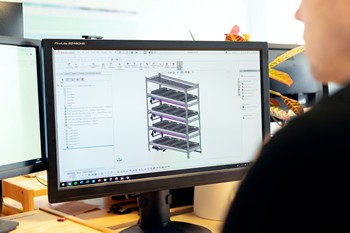

- Overall view (or General Arrangement) of what needs to be manufactured. This view / drawing gives the fabricator an overall idea of what the completed “project” looks like. This view will normally have item bubbles to show the location of the components for clarity

- Sub-assemblies are normally shown to show more in detail how components has to fit together. These drawings will be used by the fabricator during assembly.

- Sub-sub-assemblies are shown if the sub assemblies are very complex. A drawing can even have more sub-sub-sub- assemblies if the assemblies are very complex!

- Details are shown where the designer wants to make it clear how components fits together. These details differ from assembles as it does not show complete assemblies, but only how certain components fit together.

- Welding details are shown where welding is required. Often times weld symbols may be shown, but where equipment is pressure bearing a weld detail is required. The weld detail will show how the material should be prepared, how it should be welded and any grinding that may be required.

- Component or item details are shown lastly so that the manufacturer can make and prepare all the components before starting to assemble.

- Designers will (or should) also keep in mind how the equipment will be moved and installed. Future maintenance is also kept in mind. The designer should also make note of any special requirements on the drawing.

How engineering drawings are used for maintenance/modifications:

Allot of the principles and information used on a drawing that is intended for fabrication, is also used on a drawing made for maintenance purposes. In most cases the component that has to be replaced or repaired has to fit into an existing place, so a draftsman needs to measure accurately where the component should fit and make sure that the new component will fit exactly the same into the old one’s place without deviations.

In the case of modifications, the drawing should clearly show what- and how the modification is to be done.

Strength calculations, dimensional verification and material compatibility needs to be taken into account when creating the drawing. Maintenance/modification drawings also needs to comply to the relevant codes and standards.

How engineering drawings are used for tender purposes:

In cases where a client wants to replace equipment (eg, a heat exchanger, tank, drum etc.), he will request for fabricators to tender for the design, manufacture and installation. This is where the client will need a document to tell the potential designer/manufacturer what needs to be built, technical specifications, information and more.

This document is normally accompanied by drawings that gives dimensional information, so that the manufacturers can accurately base their quotation on the information supplied on the drawing.

A tender drawing is not for manufacturing, the manufacturer must still do his own design. The tender drawing should just give dimensional information and any specific details that is a requirement in the designing phase.

If the drawing is based on existing equipment that needs to be replaced, all tie-up interfaces needs to be shown accurately. The tender drawing are often used as a base for the design so all dimensions and interfaces needs to be accurate otherwise the new equipment may not fit.

Engineering drawings are considered legal documentation and are treated as such. Drawings are normally kept on a system by the designer and the client that gives traceability to the equipment. Drawing of maintenance and modification also forms part of the history of equipment and are kept with the original design drawings.